When it comes to roller bit for professional foundation work, all roads lead to Firmtech.

We have the most complete range of roller bit models for all brands!

We have a variety of piling roller drill bits for you to choose from. Suitable for different piling applications.

See the differences below for your reference.

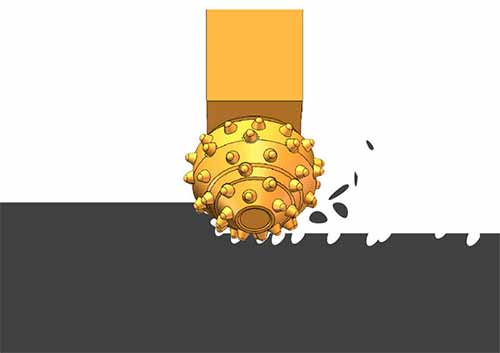

Roller bit

Best for the less chanlleging hard rock formation

· 52 alloy teeth

· Easy and fast welding

· 20CrNiMoA high hardness material

Traditional Roller bit

Large core barrel first choice

· traditional body most used in the oil and gas industry

·Regular body, no cutting required

Repaceable Roller bit

Holder type design,weld once, replace multiple times

· Weld the holder onto the core barrel

· This is replaceable design is good for a quick replaceable

(flagship Roller bit)

Best for the less chanlleging hard rock formation

· The Auto Position Leg is designed for staking and welding.

· High working efficiency

· Easy to weld

Bolt Roller Bit

Bolt type for quick replace but require special core barrel

· 52 alloy teeth

· Quick replacement

· Vacuum grease system

· Easy and stable connection

12-1/4″ Roller Bit

Big size for the large OD borehole

· 74 alloy teeth

· It is more than 60% more compare to the regular 12-1/4″ roller bit and tricone cutters

Roller bit

It adds 20 small inserts for cone guards

· Protects the cone from wear in highly abrasive environments

· Longer working life of the roller bit

FIRMTECH is the specialist for roller bit solutions and can provide you with comprehensive support in the welding and operation of roller bits, as well as problem analysis and solutions for your specific project situation.

Through years of dedicated work, FlRMTECH has earned the trust of bothdomestic and overseas markets. lt enjoys a good reputation in Shenzhenand Guangzhou and is rapidly expanding its products in South Asia, theMiddle East, and Europe.

What we do

Regular models of drilling tools in stock andquick delivery available for client’s urgent orders.

With more than a decade of international trade experience, we understand the logistics, regulations, and technical standards of markets around the world. Our global expertise guarantees smooth cooperation and reliable delivery.

Every roller bit undergoes rigorous quality inspections—from raw materials to final delivery. Our commitment to quality ensures high performance and durability, even in the most demanding drilling conditions.

With the ability to travel frequently and meet clients in person, we gain a deep understanding of on-site conditions and project requirements. This allows us to deliver precise, customized solutions that truly meet our clients’ needs.

Depending on the cutting condition and the machine types, these roller bit are typically used on core barrels for piling rotary drill rigs in gerenal. Also, they are compatible with XCMG, SANY, BAUER,SOILMEC, SUNWARD, CMV,MAIT and other brands.

MH-3 have auto angle body,4th generation automatic positioning body will help you weld the roller with ease and confidence no matter on the site or in the workshop

Bearings are made of hard alloy apply, all roller bearings are made of cemented carbide to increase hardness

Copyright by FIRMTECH.com.